Drainage pipe inspection well trenchless mortar spraying repair equipment

Wenzhou Wengong Construction Machinery Co., LTD., Wenzhou 325000, Zhejiang, China

Abstract: The normal operation of drainage pipes is directly related to the normal life of urban residents and social stability, and is the key means to deal with urban waterlogging disasters. It is very important to ensure the integrity of the inspection well because of the traffic load and the underground hydrostatic pressure outside the inspection well and the erosion of various sewage gases inside. This paper analyzes and expounds the current application technology of trenchless mortar spraying repair in inspection Wells at home and abroad and the structure and characteristics of different types of trenchless mortar spraying repair pumps and related equipment. The purpose is to improve the technology of trenchless mortar spraying repair in inspection Wells at home and abroad, so that construction units can correctly understand and use mortar spraying repair equipment.

Key words: inspection well; Lining repair; Centrifugal spraying; Mortar pump equipment

1 Introduction

With the acceleration of the urban process in our country, the construction and maintenance requirements of urban drainage pipes continue to improve. As an important auxiliary facility for the inspection, dredging, cleaning and maintenance of drainage pipes, it is particularly important to ensure their good condition. Due to the damage caused by many factors such as bad environment, traffic pressure and sewage erosion, the inspection well has various defects and diseases.

In view of the repair of damage and corrosion problems on the inner wall of inspection Wells, the trenchless centrifugal spraying process of high-strength fiber reinforced special cement mortar is currently adopted at home and abroad as the main means. The centrifugal spraying mortar technology has the characteristics of high efficiency, dense, uniform surface layer and strong adhesion, so that the inner wall of inspection Wells after repair can get high-strength coating lining. The service life and safety of inspection Wells are improved and extended. At the same time, the repair technology of centrifugal spraying mortar is simple, both round and square Wells are suitable for operation, spraying without dead corners, and it is a low-cost investment.

2 Check the mortar spraying equipment in the three elements of well mortar spraying repair

Slurry centrifugal spraying repair technology originated from APIM Company in the United States. In 2001, the spraying mortar technology developed by centriline Company in the United States in the 1930s was first applied to the structural centrifugal spraying repair process of inspection Wells, which has been widely used at home and abroad.

One of the key elements of the centrifugal spraying repair technology is the spraying material, which uses high-strength fiber reinforced anti-corrosion special mortar; The second is the construction machinery and equipment, the mortar pump and supporting mortar mixer, centrifugal rotary spraying machinery; The third is the standard construction technology.

Among them, mortar pump and supporting machinery play an important role in the quality of centrifugal spraying repair of inspection Wells, which directly affects the crack resistance, permeability resistance, bond tensile strength and various physical indexes after curing of the mortar lining of inspection Wells after repair. At the same time, the correct selection of mortar pump and supporting machinery is closely related to construction efficiency, labor intensity and construction cost.

3 Application status of centrifugal spraying repair construction equipment in foreign inspection Wells

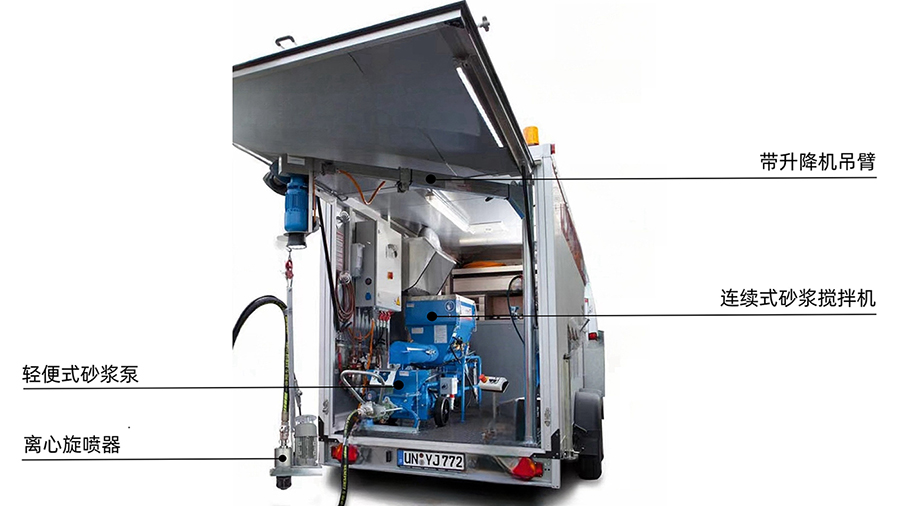

Although there is a long history of non-excavation centrifugal spraying repair in foreign inspection Wells, the application of supporting machinery for mortar pumps is different from that in China, most of them use portable mortar pumps, continuous mortar mixers and boom type centrifugal spouters independently placed in special truck cargo boxes (see FIG. 1 and FIG. 2). After the automatic continuous mixing, the mortar enters the slurry pump storage bin continuously, and is transferred by the slurry pump to the centrifugal spouter on the crane arm through the conveying pipe, resulting in the slurry being centrifugally sprayed on the inner wall of the inspection well to form a uniform, dense and new lining. Similar to this structural form of supporting spraying equipment in the domestic application is still rare, only Wuhan Zhongdi da trenchless Research Institute used (see Figure 3).

FIG. 1 Structure of centrifugal spraying repair equipment for foreign inspection Wells

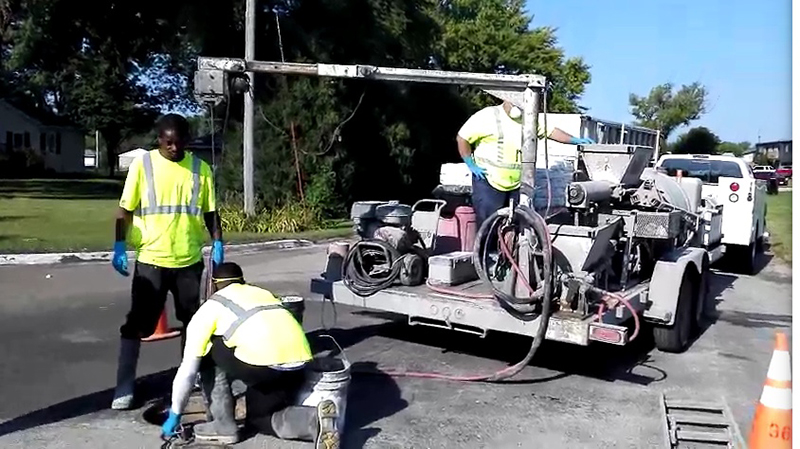

FIG. 2 Foreign inspection well mortar spraying repair operation site

The biggest feature of the use of the external continuous mixer is that the mortar pump is a screw mortar pump, which is a positive displacement pump to meet the requirements of pressure changes, and its stable work, compact structure, small size, light weight, easy manual handling, and no lifting equipment is required. The same continuous mixer has automatic metering water, quantitative feeding, dry and wet isolation area, dry powder continues to enter the wet area for mixing, and low bin position, the whole set of equipment operation is simple and convenient. It can be used either on the ground or in the van cargo box. Therefore, it is widely used in foreign countries (see Figure 3).

Figure 3 Domestic use of light inspection well repair supporting machinery

4 The application status of trenchless repair equipment for inspection Wells in China

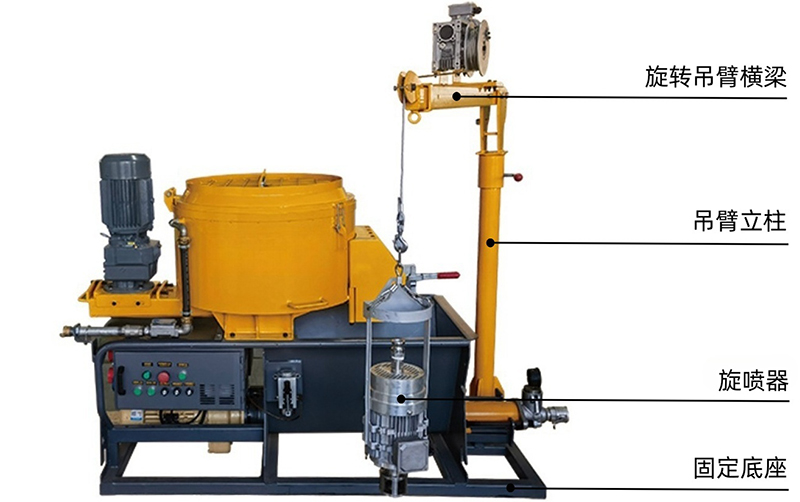

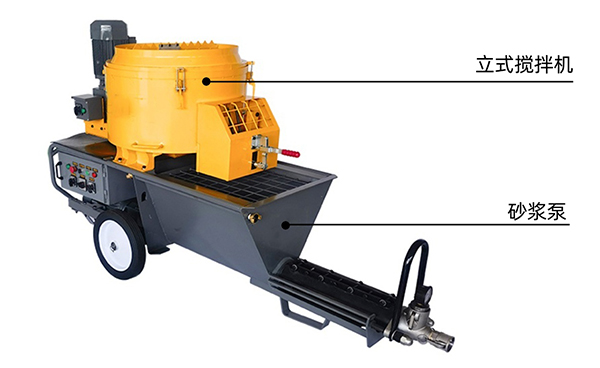

In recent years, China's urban infrastructure construction has developed rapidly, and the number of municipal pipeline construction has increased sharply. According to statistics, by the end of 2023, the national urban water supply and drainage pipeline holdings have reached 2 million kilometers. It can be seen that the number of inspection Wells repaired has increased year by year. The existing centrifugal spraying repair equipment of domestic inspection Wells is also based on mortar pumps, mixers and rotary blowers, but the difference is that the overall machine that combines mixers and mortar pumps is generally used (see Figure 4).

FIG. 4 Mortar pump and mixer integrated machine

Compared with foreign countries according to the functional classification of independent machine types with the use of worth thinking about one is the overall machine model cumbersome, loading and unloading non-lifting machinery can not be solved, followed by the use of the whole machine cleaning trouble, then maintenance, repair time-consuming, cumbersome replacement of vulnerable parts. In addition, the quality and effect of prepared mortar and pumped mortar are different due to the different overall machine structure in China.

5 Structural characteristics of centrifugal spraying repair equipment for inspection Wells in China

5.1 Check the type of centrifugal spraying equipment in the well

5.1.1 Frame type of mobile external spinner

The advantage of mobile models is that they can also operate in areas where motor vehicles cannot enter, but long-distance transport must be completed by the lifting machinery, and the external spinner and its frame are folded to occupy a larger cargo box space of the carrier (see Figure 5).

FIG. 5 Mobile external spout spout frame inspection well repair equipment

FIG. 5 Mobile external spout spout frame inspection well repair equipment

FIG. 6 Operation site of rack-type rotary jet

FIG. 6 Operation site of rack-type rotary jet

5.1.2 Truck-mounted spout boom type

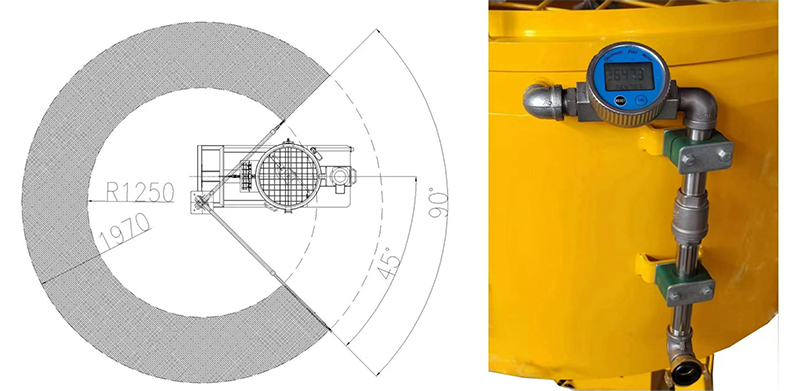

The truck type is mainly used for the repair of urban underground pipe network inspection Wells, and comes with its own spout boom. The boom structure is similar to that of foreign products, and the spout boom can be positioned on the central axis of the inspection Wells within the range of 270° rotation and 2000mm expansion length. After the operation, the boom can be placed vertically close to the column and occupy little space in the compartment (see FIG. 7 and FIG. 8).

FIG. 7 Equipment for inspection and repair of the truck-mounted spout boom type inspection well

FIG. 8 Operation range of truck-mounted rotary boom FIG. 9 Configuration of metering water supply system

FIG. 10 Operation site of boom spinner

5.2 Check the structure of the centrifugal spraying equipment in the well

The centrifugal spraying equipment structure of the inspection well is divided into two different models, namely, vertical mixer on the mortar pump and horizontal mixer on the mortar pump. No matter what kind of structure mixer is placed on the mortar pump, different product structures in China are not the same, the key is whether the configuration of the mixer blade structure is suitable for the mixing of reinforced fiber special mortar, whether it can generate strong radial flow and axial flow during the mixing process, forming a multi-flow circulating vortex, the contact surface between the mixing components is large, and the size of the slurry microclusters is small. The compact encapsulation of particulate aggregate results in sufficient mixing. At present, the market is mainly based on German putzmeister, Italian IMER, TORBOSOL technology, and there are also innovative products in foreign technology, such as strengthening the driving function, adding a metered water supply system with visual reading, improving the discharge mechanism (see Figure 9, Figure 11), and improving the mixing capacity to meet the needs of domestic mortar characteristics. At the same time to create convenient conditions for operation, maintenance and maintenance.

Side discharge mechanism Bottom discharge mechanism cylinder discharge mechanism

FIG. 11 Mixer discharging mechanism with different structure

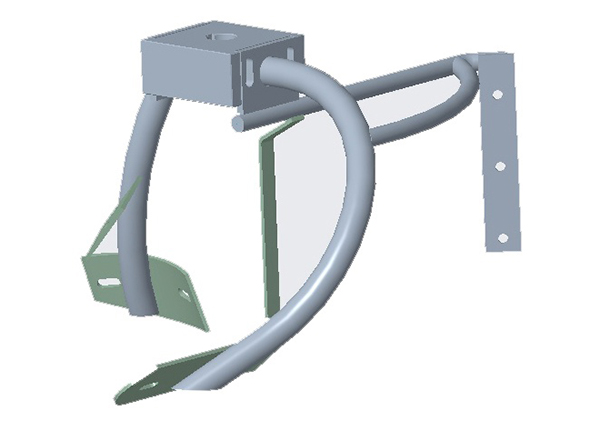

5.2.1 Upper vertical mixing machine

The upper vertical mixer (see Figure 12) has a mixing capacity of 120L, and the mixing blade of the skeleton structure (see Figure 13) and the mixing body form a cylindrical agitator. The mixing device can generate radial and axial circulating flow when mixing the slurry. The contact surface of the mixed particle aggregate is large, and good encapsulation is achieved, ensuring the cohesion and uniformity of the mix (see Figure 13).

Figure 12 Vertical mixing machine

Figure 13 Skeleton blade structure of vertical mixer

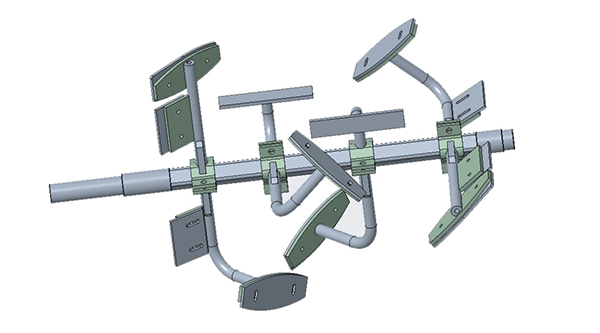

5.2.2 Set up horizontal mixing machine

The mixing capacity of the upper horizontal mixer (see Figure 14) is 220L, which is larger than that of the upper vertical mixer. The mixing blade of the upper horizontal mixer is shaped like a plough knife, and the distribution of the mixing blade along the left and right side of the master horizontal axis is reversed-alternating into intermittent helical lines (see Figure 15). This structure can promote the mixing material to produce frequent radial and axial turnover, shearing, dispersion, extrusion and mixing. It is especially obvious to improve the encapsulation of particulate aggregates in high-strength fiber-reinforced mortar.

Figure 14 Horizontal mixing machine

FIG. 15 Blade structure of horizontal mixer

6 Check the main components of the well mortar spraying repair equipment

At present, the structural difference of various mortar centrifugal spraying repair equipment in China is mainly the use of different screw pump main motor, screw pair and centrifugal jet.

Screw mortar pump is an important machine in the complete set of equipment for mortar centrifugal spraying repair in inspection Wells. Its conveying pressure is basically the same at home and abroad, within the range of 25-40bar, and the displacement is selected between 40L/min-90L/min. Its running stability directly affects the water retention and thixotropy of the pumped mortar, as well as the service life of the mortar pump.

6.1 Main motor of screw pump

The selection of 4.5/5.5-4/2KW/P three-phase asynchronous two-speed motor, low manufacturing cost, construction operations used to choose high-speed gear, due to the reduction of torque, resulting in the safety and stability of the whole machine less than the three-phase asynchronous single-speed motor.

The 7.5KW/4P asynchronous single-speed motor is selected to realize stepless speed regulation operation by installing a frequency converter. Because the motor is easy to lose the motor rotor when it runs at non-sinusoidal voltage and current, the extra heat of the motor is affected by the Skin Effect, the efficiency is reduced, and the output power is reduced.

The selection of mechanical stepless variable speed 5.5KW/4P motor is more used in foreign mortar pumps, and the domestic application is small, which has high transmission power, high overload capacity, low consumption, speed ratio and torque adjustment range, and the manufacturing cost is slightly higher, but the use cost is low. Therefore, the application of centrifugal spraying repair of mortar in inspection Wells in China will gradually increase, especially in the repair of drainage pipes and box culvert linings (see Figure 16).

FIG. 16 Mechanical stepless motor drives mortar pump

FIG. 17 Mechanical stepless variable speed motor driving mortar pump operation site

6.2 Mortar pump screw pair

The outer diameter, lead, eccentricity of the rotor and stator of the screw pair of the mortar pump, as well as the revolution of the screw pump are closely related to the working pressure, displacement and conveying distance of the mortar pump. The material and manufacturing process of the rotor and stator are determined by the wear resistance and service life, and directly affect the operating cost of the mortar pump.

Screw pump pressure calculation formula:

L-screw pump rotor length

S-screw substator leads

0.6- Working coefficient

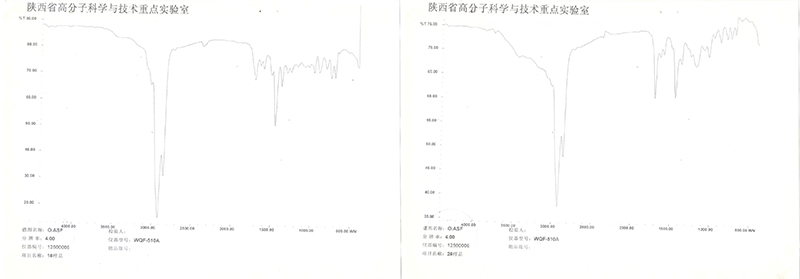

In the application of centrifugal spraying repair of screw pairs in domestic inspection Wells, there are domestic and imported products respectively, and the imported products are mainly putzmeister and PFT products from Germany. The test results of sampled stator infrared spectrum analysis are compared with those in China (see Figure 18).

Infrared spectrum of domestic thermostatic stator was examinedInfrared spectrum of foreign putzmeister stator was examined

Infrared spectrum of domestic thermostatic stator was examinedInfrared spectrum of foreign putzmeister stator was examinedFigure 18 Stator infrared spectrum detection

The analysis results of the internal elements and content of rotor materials of domestic and foreign products are compared with those of domestic products (see Figure 19).

The elements and contents of domestic thermostatic rotor materials were tested The elements and contents of foreign putzmeister rotor materials were tested

FIG. 19 Analysis of elements and contents in rotor materials

It can be seen that the material structure of screw pairs manufactured at home and abroad contains similar elements and content, and domestic products have an advantage in price performance.

6.3 Centrifugal jet injector

The centrifugal rotary nozzle is the terminal component of the mortar lining spraying repair equipment of the pipeline inspection well. It is mainly responsible for spraying the mortar transmitted by the screw pump pressure through the slurry conveying pipe evenly and continuously, and forming a new layer of dense, uniform, sturdy and durable, anti-leakage and anti-corrosion lining on the surface of the old inner wall of the pre-treated inspection well.

The foreign rotary spout is installed in the mechanical boom to control lifting and lowering, and the domestic boom control and external frame control are adopted.

The working speed of the rotary jet is generally controlled at each lifting cycle, and the thickness of the mortar layer is about 2-3mm. The inner liner thickness is controlled by adjusting the lifting speed of the spinner and the rotating speed of the spray head.

At present, the types of spinner at home and abroad are divided into single spinner and combined spinner.

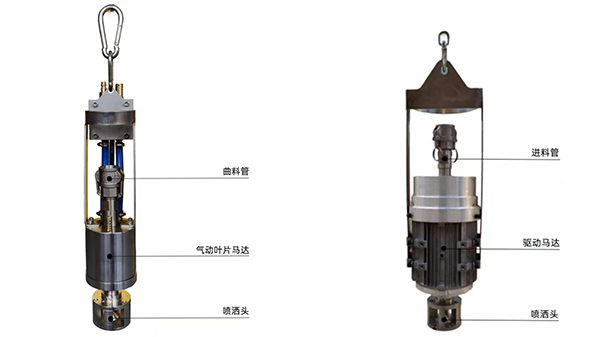

6.3.1 Single jet spout

The single type rotary spray is divided into electric and pneumatic models, the working principle is the same, respectively by the motor and the pneumatic motor rotor shaft to drive the spray head high-speed rotation, mortar input pipe through the hollow rotor shaft, directly into the spray head for radial dispersion injection.

The main feature of the pneumatic rotary jet is that the investment cost is high, and the air compressor must be configured elsewhere, and the compressed gas is the power source. The pneumatic model has higher speed than the electric model, and the spraying and atomization efficiency is high (see Figure 20).

The electric spinner has lower cost than the pneumatic spinner, no additional power source is required, and the power supply is available anywhere. Stable operation, convenient maintenance and cleaning, practical, cost-effective, widely used in China (see Figure 21).

FIG. 20 Structure of a single type pneumatic spout FIG. 21 Structure of a single type electric spout

FIG. 20 Structure of a single type pneumatic spout FIG. 21 Structure of a single type electric spout

6.3.2 Combined spout

The combined rotary jet is divided into bypass feed type and lateral drive type.

The combined bypass grouting rotary spout (see Figure 22) is connected by the vertical motor flange directly to the pipe elbow conical or cylindrical storage hopper, and the mortar enters the storage hopper through the pipe elbow to the spray head, and the spray head is connected with the motor rotor shaft, causing the mortar to rotate from the spray head for radial spraying. The by-pass slurry feeder is characterized by its simple structure and low working stability compared with the monomer rotary nozzle, and it is easy to clog the mortar storage hopper with the problem of workability.

The combined lateral drive type rotary spout (see Figure 23) is driven by the motor by belt drive or gear drive spray head rotation, to achieve radial spraying mortar. The characteristic of the lateral transmission model is that the design speed of the spray head can be greater than that of other electric rotary blowers, and it is less used in foreign countries, because the volume and weight are too large, the operation is easy to deviate from the central axis of the inspection well, and the maintenance is cumbersome.

FIG. 22 Structure of combined bypass jet injector FIG. 23 Structure of lateral drive jet injector

7 Conclusion

Drainage pipeline is an important part of urban infrastructure construction, and its normal operation plays a key role in improving urban waterlogging disaster response ability, which is directly related to the safe operation of the city and the normal life of residents and social stability. Obviously, it is of great significance to strengthen the maintenance and maintenance of drainage pipeline inspection Wells. Due to the poor operating environment of the inspection well, it is not only necessary to overcome the surrounding soil, external traffic load and underground hydrostatic pressure, but also to face the erosion of various sewage gases, which is easy to cause damage and disease of various phenomena, and must be repaired in time.

At present, the slurry centrifugal spraying repair technology and equipment has the advantages of quick and flexible repair, stable and reliable, and high cost performance, which is widely used in the municipal construction industry at home and abroad. The effect and quality of inspection shaft mortar repair by centrifugal spraying are directly related to the performance of construction equipment.

References:

[1] 严建华.预拌砂浆[M].北京:中国建筑工业出版社.2012.8.

[2] 沙克.预拌砂浆机械施工及经济分析[J].散装水泥.2011.(2).42-44.

[3] 王培铭.商品砂浆[M].北京:化学工业出版社.2008.

[4] 陕西省高分子科学与技术重点实验室WOF 201 3022综合测试分析报告[R].西北工业大学.2013.

[5] JC/T6001-2022.机械喷涂施工技术规程[S].北京:中国建材工业出版社.

[6] Putzmeister.Putzmeister Mörtelmaschinen GmbH Plastering machines, screed pumps and fine concrete pumps Catalogue 2011/2012[M]. Max-Eyth-StraBe 10·D-72631 Aichtal.Germany.2011.